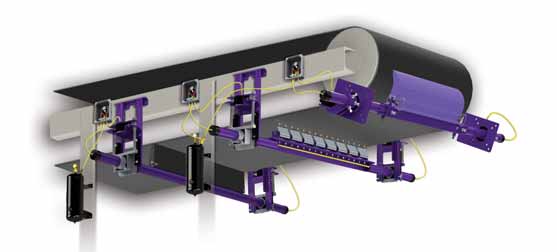

Avskrapare

Ett stort problem med många bandtransportörer är spill och ”carry back”.

Med andra ord material som fastnar på bandet och ramlar av utefter transportörens längd.

Renhållning, bortforsling av material är ofta en stor kostnad.

Du kan lösa problemet med en effektiv bandskrapa.

Vår partner Flexco har en lösning på de flesta problemen med spill.

EZP-LS “Limited Space” Förskrapa

• Kompakt design med kortare bommar

• Standardkvalitet, blad i helgjuten design

• Visuell spännare

• Gör-det-själv installation och minimalt underhåll

Maximal bandhastighet*: 500 fpm (2.5 m/sec)

Trumdiameter från 6”–22” (150–550 mm)

Tillämpningar: Brick/Block Plants, Applications: Brick/Block Plants, Ready Mix Plants,

Road/Mobile Equipment

CEMA Class 2

EZP-LS Stainless Steel Food Grade Precleaner

• Stainless steel components for superior corrosion resistance

• Standard-duty, solid-blade design

• Visual tension check

• White food-grade, chemical-resistant ConShear™ blade

Maximum Belt Speed*: 500 fpm (2.5 m/sec)

Pulley Diameter from 6”–22” (150–550 mm)

Applications: Fermentation Byproducts, Pre-processed Foods

CEMA Class 2

EZP-LS High-Temp Precleaner

• Compact design with shorter pole length

• Standard-duty, solid-blade design rated up to 275° F (135° C)

• Can handle temperature spikes to 325° F (163° C)

• Visual tension check

• Do-it-yourself installation and minimal maintenance

Maximum Belt Speed*: 500 fpm (2.5 m/sec)

Pulley Diameter from 6”–22” (150–550 mm)

Applications: Coke, Clinker, Cement, Asphalt

CEMA Class 2

EZP1 Precleaner

• Standard-duty, with 2 3/8” (60 mm) diameter pole

• Visual tension check

• Requires just 4″ (100 mm) of horizontal clearance

• Do-it-yourself installation and minimal maintenance

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 10”–36” (250–900 mm)

Applications: Aggregate, Sand & Gravel, Cement,

Wood Processing, Recycling

CEMA Class 3

EZP1 High-Temp Precleaner

• Standard-duty, solid-blade design rated up to 275° F (135° C)

• Can handle temperature spikes to 325° F (163° C)

• Visual tension check

• Requires just 4″ (100 mm) of horizontal clearance

• Do-it-yourself installation and minimal maintenance

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 10”–36” (250–900 mm)

Applications: Coke, Clinker, Cement, Asphalt

CEMA Class 3

EZP1 Stainless Steel Food Grade Precleaner

• Stainless steel components for superior corrosion resistance

• Standard-duty, solid-blade design

• Visual tension check

• White food-grade, chemical-resistant ConShear™ blade

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 10”–36” (250–900 mm)

Applications: Fermentation Byproducts, Pre-processed Foods

CEMA Class 3

EZP1 Twist Tensioner Precleaner

• Standard-duty, solid-blade design

• Compact torsion twist tensioner allows for measurable

and verifi able tension

• Tensioner compatible to mount on either end of pole

• Do-it-yourself installation and minimal maintenance

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 10”–36” (250–900 mm)

Applications: Aggregate, Sand & Gravel, Cement,

Wood Processing, Recycling

CEMA Class 3

EZP1 Precleaner with White ConShear™ Blade

• Standard-duty, with 2 3/8” (60 mm) diameter pole

• Visual tension check

• Requires just 4″ (100 mm) of horizontal clearance

• Do-it-yourself installation and minimal maintenance

• White food-grade, chemical-resistant ConShear blade

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 10”–36” (250–900 mm)

Applications: Fermentation Byproducts, Pre-processed Foods

CEMA Class 3

MSP Standard Mine-Duty Precleaner

• Standard Mine-Duty, with 2 7/8” (73 mm) diameter rugged pole design

• Do-it-yourself installation and easy maintenance

• Visual tension check

• Highly effective cleaning

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 16”–42” (400–1050 mm)

Applications: Aggregate, Sand & Gravel, Cement,

Wood Processing, Recycling

CEMA Class 3

*Belt speeds can be higher in vulcanized applications.

Stainless Steel MSP Standard Mine-Duty Precleaner

• Stainless steel components for superior corrosion resistance

• Mine-duty, solid-blade design

• Do-it-yourself installation and easy maintenance

• Visual tension check

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Pulley Diameter from 16”–42” (400–1050 mm)

Applications: Phosphate, Potash, Salt

CEMA Class 3

H-Type® HXF2 Precleaner

• Suitable as a stand-alone cleaner in standard and

medium duty applications

• Available with polyurethane

Maximum Belt Speed*: 1000 fpm (5.0 m/sec)

Pulley Diameter from 10” – 53” (250– 325 mm)

Applications: Underground Mining, Hard Rock Mining,

Metal Mining, Aggregate

CEMA Class 4

H-Type® High-Temp HV Precleaner

• Tungsten carbide tips provide superior cleaning effi ciency

(vulcanized belts only)

• Segmented blades work independently

• Visual tension check

Maximum Belt Speed*: 1000 fpm (5.0 m/sec)

Pulley Diameter from 10”–63” (250– 575 mm)

Applications: Power Plants, Port Facilities, Iron Ore, Steel Mills

CEMA Class 3

H-Type® HV/HVP Precleaner

• Tungsten carbide tip provides superior cleaning effi ciency

(vulcanized belts only)

• Segmented blades work independently

• Visual tension check

Maximum Belt Speed*: 1500 fpm (7.5 m/sec)

Pulley Diameter from 10”–63” (250–1575 mm)

Applications: Power Plants, Port Facilities, Hard Rock Mining,

Iron Ore, Steel Mills

CEMA Class 4

HV2 Precleaner

• Tungsten carbide tip provides superior cleaning effi ciency

(vulcanized belts only)

• 6″ (150mm) segmented blades work independently

• Adjustable cushions allow for enhanced pulley conformance

• Visual tension check

Maximum Belt Speed*: 1500 fpm (7.5 m/sec)

Pulley Diameter from 10”–67” (250–1675 mm)

Applications: Power Plants, Port Facilities, Hard Rock Mining,

Iron Ore, Steel Mills

CEMA Class 4

PAT Portable Air Tensioner

• PAT ensures constant tension for full blade

life with little maintenance

• Works with Flexco mechanical fasteners

• Usable with air, nitrogen or water

• Offers single or dual tank (for two cleaners)

when site air is not available

• Featured on Mineline®-approved cleaners like

MMP, MHP, MHCP, MHS and MDWS

MHCP Heavy-Duty Cartridge Precleaner

• One of the most rugged precleaners available

• Engineered for abusive conditions

• Telescoping, 3-piece pole that resists twisting/bowing/bending

• Quick-change SuperShear™ blade cartridge for fast,

easy maintenance

Maximum Belt Speed*: 1200 fpm (6.0 m/sec)

Pulley Diameter from 20”–48” (500–1200 mm)

Applications: Underground Mining, Hard Rock Mining, Metal Mining,

Longwall Coal Mining, Steel Mills, Iron Ore

CEMA Class 5

MHP Heavy-Duty Precleaner

• Heavy-duty, solid blade precleaner

• Heavy 3-piece pole design with rugged, dual-spring tensioners

• Abrasion-resistant, XL solid polyurethane MegaShear™ blade

Maximum Belt Speed*: 1500 fpm (7.5 m/sec)

Pulley Diameter from 20″– 84″ (500–2100 mm)

Applications: Underground Mining, Hard Rock Mining, Metal Mining,

Longwall Coal Mining, Steel Mills, Iron Ore

CEMA Class 5

Stainless Steel MMP Medium-Duty Precleaner

• Stainless steel components for superior corrosion resistance

• Medium-duty mining precleaner

• Heavy-duty, 3-piece design, corrosion-resistant pole

with dual tensioners

• Visual tension check

Maximum Belt Speed*: 1000 fpm (5.0 m/sec)

Pulley Diameter from 16”–48” (400–1200 mm)

Applications: Phosphate, Potash, Copper/Gold Mining, Salt,

Load-out Facilities Near Salt Water

CEMA Class 4

MMP Medium Mine-Duty Precleaner

• Medium-duty mining precleaner with TuffShear™ blade

• Heavy-duty, 3-piece design pole with dual tensioners

• Visual tension check

Maximum Belt Speed*: 1000 fpm (5.0 m/sec)

Pulley Diameter from 16”–48” (400–1200 mm)

Applications: Underground Mining, Hard Rock Mining, Steel Mills, Iron Ore,

Metal Mining, Aggregate, Coal Fired Power Plants, Load-out Facilities

CEMA Class 4

MHS Heavy-Duty and Reversing

Secondary Cleaner

• Segmented blades with choices of tungsten carbide tips

• Patented PowerFlex™ cushions that maintain optimal belt contact

• Tensioners and cushion create 4 points of relief, making the

cleaner fastener-friendly

• Two-way cushions available for reversing applications on

shuttle conveyors, conveyors that roll back, or tripper and

stacker applications

Maximum Belt Speed: C-Tip: 1200 fpm (6.0 m/sec)

V-Tip: 1500 fpm (7.5 m/sec)

Applications: Underground Mining, Hard Rock Mining, Metal Mining,

Aggregate, Load-out Facilities, Iron Ore, Steel Mills, Power Plants

CEMA Class 5

FMS Flexco Medium-Duty Secondary Cleaner

• Available with C-tips for mechanical fastener applications

or V-tips for vulcanized applications

• Cleaning effi ciency of segmented tungsten carbide blades

• Compact MST spring tensioning system

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Underground Mining, Hard Rock Mining, Metal Mining,

Aggregate, Load-out Facilities, Iron Ore, Steel Mills, Power Plants

CEMA Class 4

R-Type® Cartridge Secondary Cleaner

• Available with C-tips for mechanical fastener applications

or V-tips for vulcanized applications

• Two-way cushions that accommodate reversing belts

• Bolt-up tensioning system

• Service Advantage Cartridge feature allows for easy service

and inspection

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Aggregate, Sand & Gravel, Cement, Wood Processing,

Recycling, Light Mining, Ideal for Power Plants with Vulcanized Belts

CEMA Class 4

R-Type® Reversing Secondary Cleaner

• Available with C-tips for mechanical fastener applications

or V-tips for vulcanized applications

• Two-way cushions that accommodate reversing belts

• Do-it-yourself installation

• Bolt-up tensioning system

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Aggregate, Sand & Gravel, Cement, Wood Processing,

Recycling, Light Mining, Power Plants with Vulcanized Belts

CEMA Class 4

P-Type® Cartridge Secondary Cleaner

• Available with C-tips for mechanical fastener applications

or V-tips for vulcanized applications

• Bolt-up tensioning system

• Service Advantage Cartridge feature allows for

easy service and inspection

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Aggregate, Sand & Gravel, Cement, Wood Processing,

Recycling, Light Mining, Ideal for Power Plants with Vulcanized Belts

CEMA Class 4

P-Type® Secondary Cleaner

• Available with C-tips for mechanical fastener applications

or V-tips for vulcanized applications

• Segmented, tungsten carbide blades

• Bolt-up tensioning system

• Limited space model option for telescoping, stacking,

or portable conveyors

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Aggregate, Sand & Gravel, Cement, Wood Processing,

Recycling, Light Mining, Power Plants with Vulcanized Belts

CEMA Class 4

High-Temp EZS2 Secondary Cleaner

• Temperature range to up to 400° F (205° C)

• Segmented tungsten carbide blades

• Patented FormFlex™ cushions maintain optimal belt contact

• Do-it-yourself installation

• Bolt-up tensioning system

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Applications: Cement, Asphalt

CEMA Class 3

EZS2 Secondary Cleaner

• Segmented tungsten carbide blades

• Patented FormFlex™ cushions that maintain optimal

belt contact

• Do-it-yourself installation

• Bolt-up tensioning system

Maximum Belt Speed*: 700 fpm (3.5 m/sec)

Applications: Aggregate, Sand & Gravel, Cement

CEMA Class 3

Y-Type Secondary Cleaner–Tungsten Carbide

• Available in standard duty (belt widths 18″-48″ (450-1200mm)

and heavy duty (belt widths 36″-72″ (900-1800mm)

• Segmented tungsten carbide blades compatible with

mechanical fastener applications are easily serviced utilizing a

removable cartridge

• Spring tensioned to deliver optimal cleaning performance and

blade life

• Compatible with reversing belts

Maximum Belt Speed*: SD 600 fpm (3 m/sec); HD 750 fpm (3.75 m/sec)

Applications: Aggregate, Sand & Gravel, Cement, Mining

CEMA Class 3

Y-Type Secondary Cleaner–Polyurethane

• Available in standard duty (belt widths 18″-48″ (450-1200mm)

and heavy duty (belt widths 36″-72″ (900-1800mm)

• Segmented tips easily serviced utilizing a removable cartridge

• Spring tensioned to deliver optimal cleaning performance and

blade life

• Food grade/chemical resistant polyurethane option available

• Compatible with reversing belts

Maximum Belt Speed*: SD 600 fpm (3 m/sec); HD 750 fpm (3.75 m/sec)

Applications: Aggregate, Sand & Gravel, Cement

CEMA Class 2 (Y-Type Standard-Duty Polyurethane)

CEMA Class 3 (Y-Type Heavy-Duty Polyurethane)

U-Type® Secondary Cleaner

• U-shaped blade and offset pole that intensify cleaning power

• Blade tips that scrape off stubborn carryback, while rubber

backers “squeegee” wet material

• Best for cupped belts and belts with worn centers

• Choice of tungsten carbide, impact-resistant tungsten

carbide, or polyurethane blade tips

• Works best in wet applications

• Blade replacement made easy with removable front plate

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Cement, Coal Mining, Coal Prep Plants, Power Plants,

Load-out Facilities

CEMA Class 5

MDWS Dry Wipe Secondary Cleaner

• Removes excess water to ensure a dry return trip

down the belt line

• Ideal for systems using a water spray pole

• Do-it-yourself installation and minimal maintenance

Maximum Belt Speed: 1000 fpm (5.0 m/sec)

Applications: Underground Mining

CEMA Class 4

Motorized Brush Cleaner

• Uniquely patterned bristles aid in reducing material

buildup and clogging

• Adjustable tensioners allow easy brush-to-belt

adjustment as the bristles wear

• Spins opposite the belt direction for optimal cleaning

• Do-it-yourself installation and quick drum replacement

Maximum Belt Speed: 700 fpm (3.5 m/sec)

Applications: Wood Chipping, Sand

CEMA Class 4

Chevron Secondary Cleaner

• For raised top, chevron, or grooved belts

• Hundreds of rubber fi ngers that fl ick off carryback

• Free-rotating design that works only when the belt runs

• Do-it-yourself installation and quick drum replacement

Maximum Belt Speed: 500 fpm (2.5 m/sec)

Applications: Wood Chipping, Sand

CEMA Class 3

Stainless Steel U-Type® Secondary Cleaner

• Stainless steel components for extra corrosion resistance

• U-shaped blade and offset pole that intensify cleaning power

• Blade tips that scrape off stubborn carryback, while rubber

backers “squeegee” wet material

• Best for cupped belts and belts with worn centers

• Choice of tungsten carbide, impact-resistant tungsten

carbide, or polyurethane blade tips

• Blade replacement made easy with removable front plate

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Load-out Facilities, Power Plants

CEMA Class 5

MHS Secondary Cleaner with Service Advantage

Cartridge™

• Segmented blades with choices of tungsten carbide tips

• Patented PowerFlex™ cushions maintain optimal belt contact

• Tensioners and cushion create 4 points of relief, making the

cleaner fastener-friendly

• Service Advantage Cartridge feature allows for easy service

and inspection

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Underground Mining, Hard Rock Mining, Metal Mining,

Aggregate, Load-out Facilities, Iron Ore, Steel Mills, Power Plants

CEMA Class 5

Stainless Steel MHS Heavy-Duty

Secondary Cleaner

• Stainless steel components for extra corrosion resistance

• Segmented blades with choices of tungsten carbide tips

• Patented PowerFlex™ cushions maintain optimal

belt contact

• Tensioners and cushion create 4 points of relief, making the

cleaner fastener-friendly

Maximum Belt Speed: C-Tip: 1000 fpm (5.0 m/sec)

V-Tip: 1200 fpm (6.0 m/sec)

Applications: Salt, Copper/Gold Mining, Phosphate, Potash, Load-out Facilities

CEMA Class 5

Precleaner Options

- CONSHEAR™ LS

- CONSHEAR™ STANDARD

- CONSHEAR™ HIGH TEMP

- CONSHEAR™ WHITE

- TUFFSHEAR™

- MEGASHEAR™

- SUPERSHEAR™

- HXF2

- HVP

- HV & HV2

| Application description | EZP-LS | EZP1 | EZP1 High Temp | MSP | MMP | MHP | MHCP | H-type (XF2 & XF) | H-Type (HV & HV2) | High Temp V-Tip |

|---|---|---|---|---|---|---|---|---|---|---|

| Belt Width* | 12''-60'' | 12''-72'' | 12''-72'' | 24''-84'' | 24''-96'' | 24''-96'' | 18''-72'' | 18''-72'' | 18''-72'' | 18''-48'' |

| 300-1500mm | 300-1800mm | 300-1800m | 600-2100mm | 600-2400MM | 60-2400 MM | 450-1800 mm | 450-1800 mm | 450-1800 mm | 450-1200 mm | |

| Belt Speed** | ||||||||||

| 2.5m/sec | 3.5m/sec | 3.5m/sec | 3.5m/sec | 5.0m/sec | 7.5m/sec | 6.0m/sec | 5.0m/sec | 7.5m/sec | 5.0m/sec | |

| Head Pulley Diameter | 6'' - 22'' | 10''-36'' | 10''-36'' | 16''-42'' | 16''-48'' | 20''-84'' | 20''-48'' | 10''-47'' | 10''-67'' | 8''-35'' |

| 150-550mm | 250-900mm | 250-900mm | 400-1050mm | 400-1200mm | 500-2100mm | 500-1200mm | 250-1175mm | 250-1675mm | 200-875mm | |

| Temperature Range | -30 till 180°F | -30 till 180°F | Upp till 275°F (135°C) med toppar till 325°F (163°C) | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | Upp till 400°F (204°C) med toppar till 450°F (232°C) |

| -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | |||

| Blade | ConShear LS | ConShear | ConShear | ConShear | TuffShear | MegaShear | SuperShear | HXF, HXF2 | HV | HV |

| Revising Belts | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Mechanical Fasteners | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No | Yes |

*Special sizes available upon request.

**Belt speeds can be higher in vulcanized applications

Secondary Cleaner Options

- C Tip

- RV Tip

- PV Tip

- UF Blade

- Uc/Uv Blade

- Dry Wipe

- Y-type Urethane

- Y-type Carbide

- Chevron

- Motorized Brush Cleaner

| Application description | EZS2 (C-Tip) | FMS (V-Tip) | FMS (C-Tip) | MHS (V-Tip) | MDWS | P-Type (C-Tip) | P-Type (V-Tip) | P-Type LS (C-Tip) | U-Type (F-Blade) | U-Type (C-Blade) | U-Type (V-Blade) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Belt Width* | 18''-72'' | 24''-84'' | 24''-96'' | 24''-96'' | 24''-96'' | 18''-72'' | 18''-72'' | 18''-54'' | 18''-84'' | 18''-84'' | 18''-84'' |

| 450-1800mm | 600-2100mm | 600-2400mm | 600-2400mm | 600-2400mm | 450-1800mm | 450-1800mm | 450-1350mm | 450-2100mm | 450-2100mm | 450-2100mm | |

| Belt Speed** | <700 fpm | <1200 fpm | <1000 fpm | <1500 fpm | <1000 fpm | <1000 fpm | <1200 fpm | <1000 fpm | <1000 fpm | <1200 fpm | <1500 fpm |

| 3.5m/sec | 6.0m/sec | 5.0m/sec | 7.5m/sec | 5.0m/sec | 5.0m/sec | 6.0m/sec | 5.0m/sec | 5.0m/sec | 6.0m/sec | 7.5m/sec | |

| Temperature Range | -30 till 200°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F |

| -35 till 93°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | |

| Reversing Belts | No | No | Yes | Yes | Yes | No | No | No | No | No | No |

| Work with Mechanical Fasteners | Yes | No | Yes | No | Yes | Yes | No | Yes | Yes | Yes | No |

| Application description | R-Type (C-Tip) | R-Type (V-Tip) | EZS2 High Temp | Y-Type SD Polyurethane | Y-Type HD Polyurethane | Y-Type SD Carbide | Y-Type HD Carbide | Chevron | Mothorized Brush Cleaner |

|---|---|---|---|---|---|---|---|---|---|

| Belt Width* | 18''-72'' | 18''-72'' | 18''-72'' | 18''-48'' | 36''-72'' | 18''-48'' | 36''-72'' | 18''-60'' | 18''-84'' |

| 450-1800mm | 450-1800mm | 450-1800mm | 450-1200mm | 900-1800mm | 450-1200mm | 900-1800mm | 450-1500mm | 450-2100mm | |

| Belt Speed** | <1000 fpm | <1200 fpm | <700 fpm | <600 fpm | <750 fpm | <600 fpm | <750 fpm | <500 fpm | <700 fpm |

| 5.0m/sec | 6.0m/sec | 3.5m/sec | 3.0m/sec | 3.8m/sec | 3.0m/sec | 3.8m/sec | 2.5m/sec | 3.5m/sec | |

| Temperature Range | -30 till 180°F | -30 till 180°F | Upp till 400°F (204°C) med toppar till 450°F (232°C) | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -30 till 180°F | -20 till 180°F |

| -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -35 till 82°C | -29 till 82°C | ||

| Reversing Belts | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | No |

| Work with Mechanical Fasteners | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

*Special sizes available upon request.

**Belt speeds can be higher in vulcanized applications